FAQs | Custom Steel Forging Services for OEM's

Forging Capabilities & Process.

Donlouco is a supplier of quality-assured steel forgings to customers primarily in the hydraulics industry. Forging is a cost-effective manufacturing process to produce very tough and strong components with excellent grain structure.

Most forgings will require secondary finishing such as CNC machining before being delivered to customers, which is something that Donlouco also manage.

Do you offer multi-stage forging?

Yes. We design and produce multi-stage forging processes up to 6 stages when required for complex geometries or high forging ratios.

Multi-Stage Forging Process:

Closed-Die Drop Forging is Widely Used in Manufacturing Parts.

Stage 1 (Pre-form): Rough material distribution into basic shape.

Stage 2 (Blocker): Progressive forming with material flow optimisation.

Stage 3-6 (Optional): Additional forming stages for complex geometries.

Final (Finisher): Final dimensions with minimal flash.

Trim Die: Removes excess flash at parting line.

When Multi-Stage Forging is Needed:

Forging ratio >1:4.

Very complex geometries.

Tight dimensional tolerances.

Parts with significant geometry variation.

Extreme thickness transitions.

Learn more about our forging process for steel parts.

What is the difference between die forging and open hammer forging?

Both are hot forging processes but suited to different applications:

Die Forging (Closed-Die):

Uses precision-machined dies (upper and lower halves)

Precise shape control and tolerances (±0.5-1.0mm typical)

Material forced into die cavity under high tonnage

Ideal for: Medium-high volumes (1,000+ parts/year), repeatability critical, tolerances important

Capacity: 1,600 tons, parts 0.5-50kg

Open Hammer Forging:

Heated blank repeatedly struck with open-faced hammers

Flexible, manual process

Less precise but faster for low volumes

Ideal for: Prototypes, low volumes (1-500 parts), one-off forgings, large parts

Capacity: 50-200+ kg parts, larger dimensions possible

What forging ratio capability do you have?

Donlouco can achieve forging ratios up to 1:6.5 in our die forging process.

What is Forging Ratio? The ratio of raw material cross-section to finished part cross-section. Higher ratios indicate more material deformation and better grain flow.

Why Forging Ratio Matters:

Higher ratio (1:5 to 1:6.5): More deformation = better grain structure alignment, superior strength and toughness

Lower ratio (1:2 to 1:3): Less deformation = simpler dies, but grain structure not optimally aligned

Example:

Raw blank: 120mm diameter

Finished part: 40mm × 40mm cross-section

Forging ratio: 1:6.5

Result: Excellent grain flow, superior fatigue resistance

High forging ratios often require multi-stage forging (2-4 stages) to progressively deform material and achieve final shape.

Our Forged Parts Manufactured From All Steel Grades.

Materials & Steel Grades.

What steel grades can you forge?

Donlouco forges all common carbon, alloy, and stainless steel grades. We can also source custom alloys upon request.

Standard Carbon Steels:

1020 (low carbon, general purpose)

1045 (medium carbon, good strength/ductility balance)

1060, 1070, 1080 (high carbon, high strength)

Standard Alloy Steels:

4140 (chromium-molybdenum, excellent all-around properties)

4340 (nickel-chromium-molybdenum, superior strength/toughness)

8620, 8640 (ideal for case hardening)

Standard Stainless Steels:

304, 316 (austenitic, corrosion resistant)

410, 420 (martensitic, heat treatable)

Custom Alloys Available:

Tool steels (H13, D2, S7)

Duplex stainless steels

Precipitation-hardening stainless (17-4 PH)

Nickel alloys (Inconel, Monel)

Titanium alloys (for critical aerospace applications)

How to Select Material:

Strength requirements → 1045, 4140, or 4340

Corrosion resistance → 304, 316 stainless

Wear resistance → High-carbon or tool steels

Cost sensitivity → Carbon steel (1020, 1045)

European standards compliance → CE-marked materials with traceability

All materials supplied with full mill certificates and traceability records. All steel grades used in manufacturing meet customer requirements and European standards.

Do your materials come with mill certificates?

Yes, 100% of all materials ship with full mill certificates as standard.

Mill Certificate Includes:

Material grade and batch number.

Chemical composition (verified per specification).

Mechanical properties (yield strength, tensile, elongation).

Test method and testing date.

Mill name and identification.

Traceability identification.

Additional Certifications Available:

PMI (Positive Material Identification) testing if required.

3.1 inspection certificates (more detailed than standard mill cert).

Material datasheets with European standards compliance.

Custom certifications per customer requirement.

Why Mill Certificates Matter:

Prove compliance with material specification.

Enable traceability to original raw material.

Required for aerospace, automotive, and safety-critical applications.

Support your company's quality documentation.

Quality & Testing.

How Does Donlouco Ensure Every Batch of Parts Meets Quality Requirements?

Regular Quality Checks are Carried Out by Engineers.

Forged parts can be fully tensile and impact tested at the approval stage and by sampling as required. All parts are fully checked and inspected before shipping with full traceability and reports available with all shipments.

Other quality checks regularly carried out during the manufacturing process include:

Visual inspections.

Dimensional checks.

Donlouco is EN 1090 and ISO 9001 approved for the CE Stamping of parts. ISO 9001 is an internationally recognised standard for Quality Assurance.

Industries and Components.

What Industries Does Donlouco Serve?

Donlouco predominately serves OEMs in the automotive, industrial tools, hydraulics, and material handling industries that require heavy-duty forged steel components.

Donlouco supplies many types of forged parts to the hydraulics industry in Ireland and the UK.

Learn more about the industries Donlouco works closely with.

What Types of Forged Parts Does Donlouco Produce?

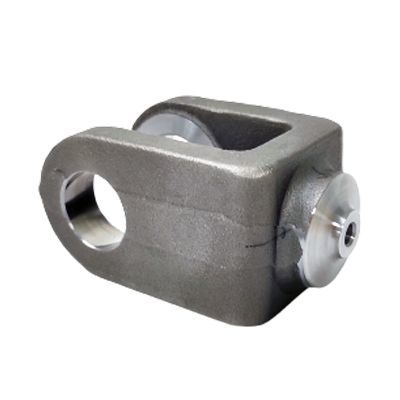

Donlouco manufactures and supplies a wide range of customer-specific parts mainly for the hydraulics industry. These parts include but are not limited to cylinder bases, flanged components, forged cylinder rod ends, forged and machined hydraulic cylinder trunnions, and forged hydraulic cylinder clevis.

Learn more about the hydraulic cylinder parts we supply.

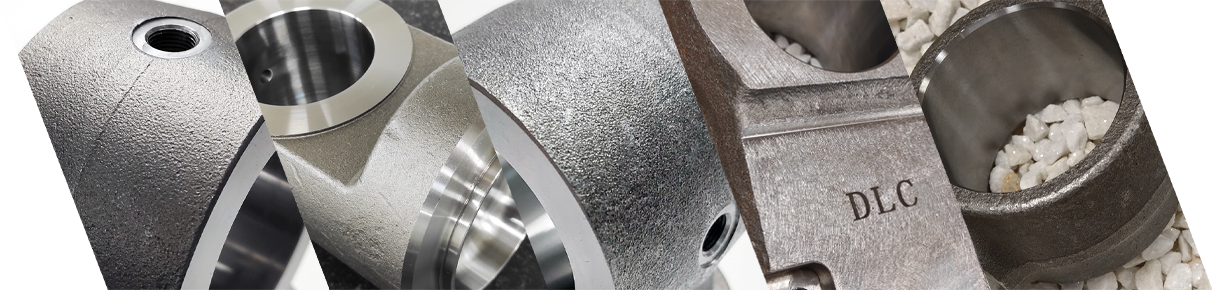

What Secondary Processes Can Donlouco Offer for Forged Parts?

Depending on the requirements of the parts, forgings can be subjected to secondary finishing operations before the parts are ready for the customer. Additional steps may include secondary CNC milling or drilling. Finishing techniques such as dipping, sandblasting and shot blasting can be used to create the desired surface finish.

Forged Parts can be Secondary CNC Machined to Exact Customer Requirements.

What is the Tooling Process for Forged Parts?

Forging tools are designed and managed and can be reversed-engineered from finished part drawings by Donlouco.

Where tools and fixtures are required to make parts, which is typically the case, Donlouco manages all of these activities directly. This includes tooling companies, subcontractors and in some cases raw material suppliers with no drain on resources from the customer.

Our tooling services include tooling for forged and cast parts requiring secondary machining and parts requiring complex fixtures to achieve reliable and repeatable accuracy at all times.